Comparison of Phosphide Sweat and Scab Defects in Grey Cast Iron Castings

In grey cast iron foundry, surface defects such as scabs and phosphide sweat are among the most common anomalies. Accurate identification of these defects is critical for applying the correct corrective measures.

Scab Defect:

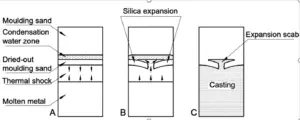

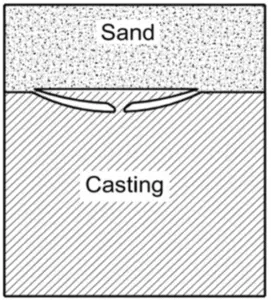

The scab defect is typically caused by mold sand expansion and metal penetration into cracks formed by steam from moisture in the mold. This defect is characterized by raised, crusty areas on the casting surface, often containing visible sand particles beneath the outer shell. The crust has a rough appearance and a structure similar to the base metal.

Phosphide Sweat Defect:

Unlike scabs, phosphide sweat is caused by thermal concentration and phosphorus segregation in thin-walled sections of the casting. During solidification, phosphorus concentrates in the last portions of the molten metal and forms steadite (an iron-phosphide eutectic phase). This results in a phosphorus-rich surface layer without sand entrapment. It typically appears in areas with shrinkage and has a smooth, flat surface aligned with the casting contour.

Key Differences:

| Feature | Scab Defect | Phosphide Sweat |

|---|---|---|

| Sand Presence | Sand particles visible beneath shell | No sand present |

| Shrinkage Association | Not typically associated | Often seen in shrinkage zones |

| Microstructure | No steadite phase | Steadite phase clearly visible |

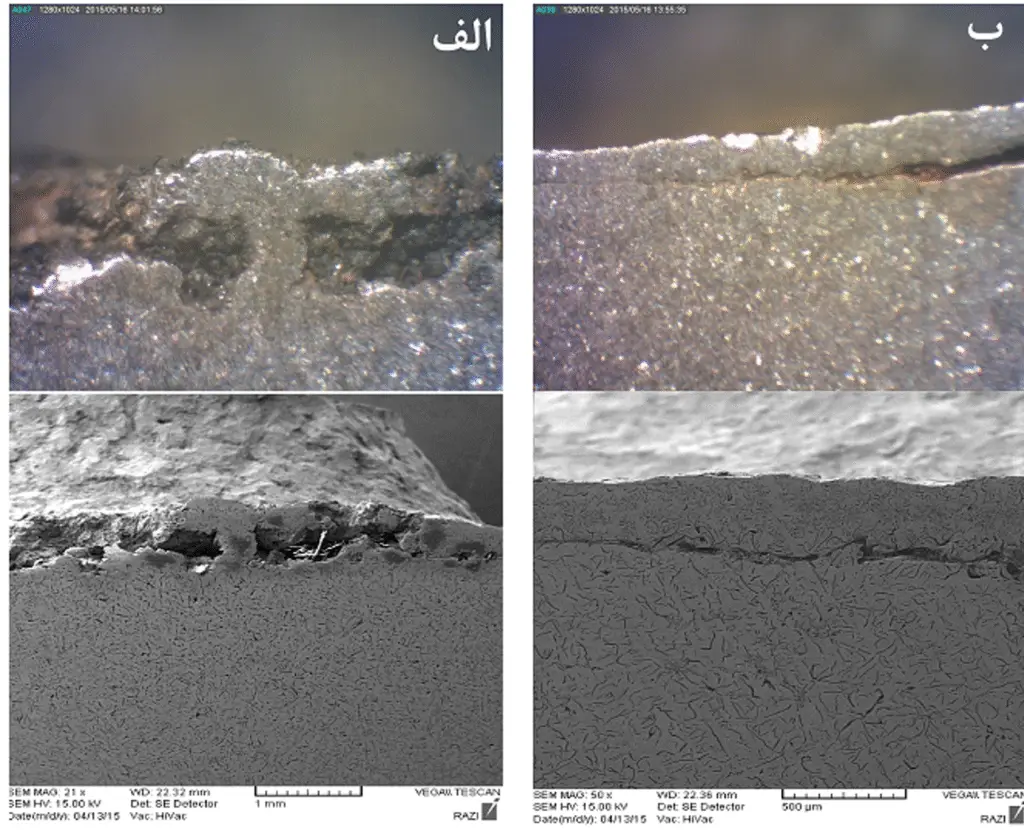

Microscopic and stereographic images:

(a) Scab Defect (b) Phosphide Sweat

Identification Methods:

These two defects can be clearly differentiated using:

-

Optical Microscopy

-

Stereomicroscopy

-

Scanning Electron Microscopy (SEM)

-

Point-wise Elemental Analysis (e.g., EDS/EDX)

Conclusion:

Misidentification of these defects may lead to inappropriate corrective actions. A precise understanding of their structural and metallurgical differences, especially in green sand mold and DISAMATIC lines, is essential for improving casting quality.

For access to the full article or to receive technical assistance, feel free to contact our team at ARAD FOUNDRY ANALYSIS Engineering Co. We are ready to help