⚙️ Design and Construction of a One-Ton Green Sand Mixer with Optimized Performance

Project Overview:

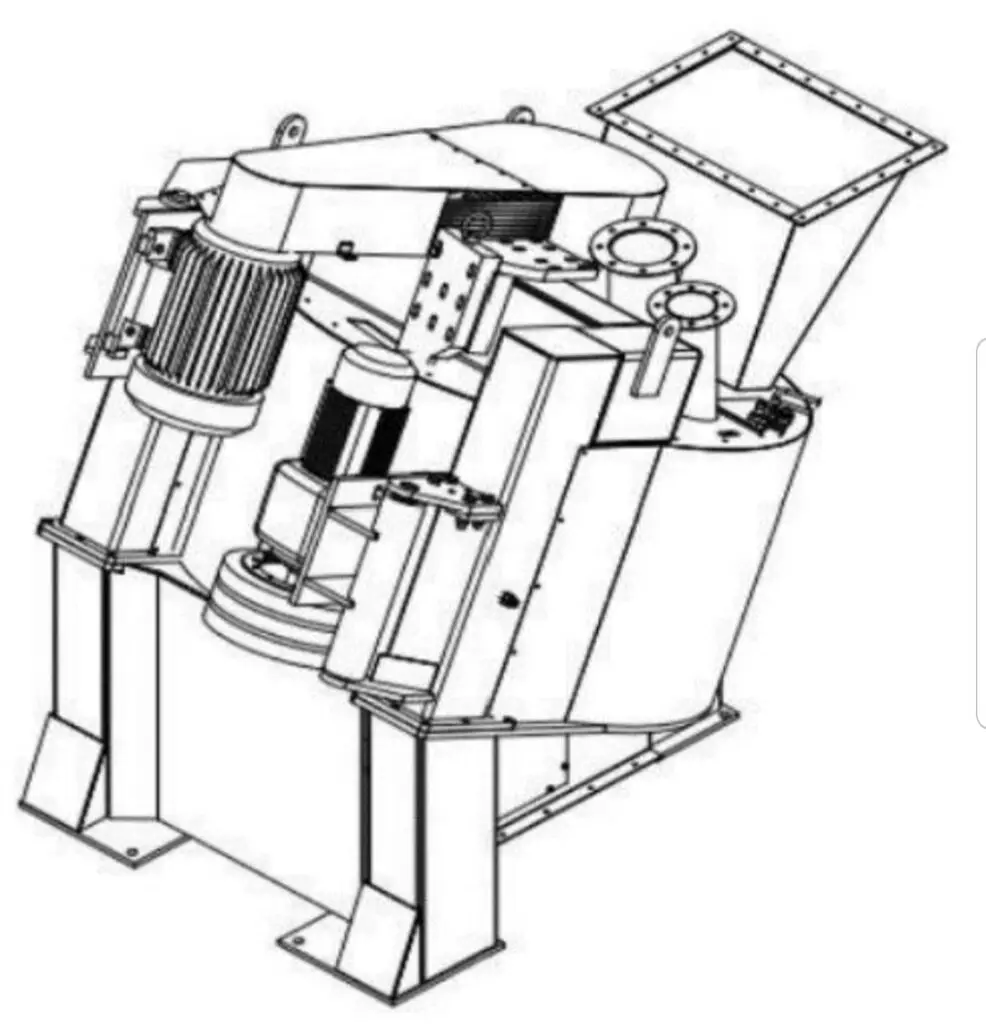

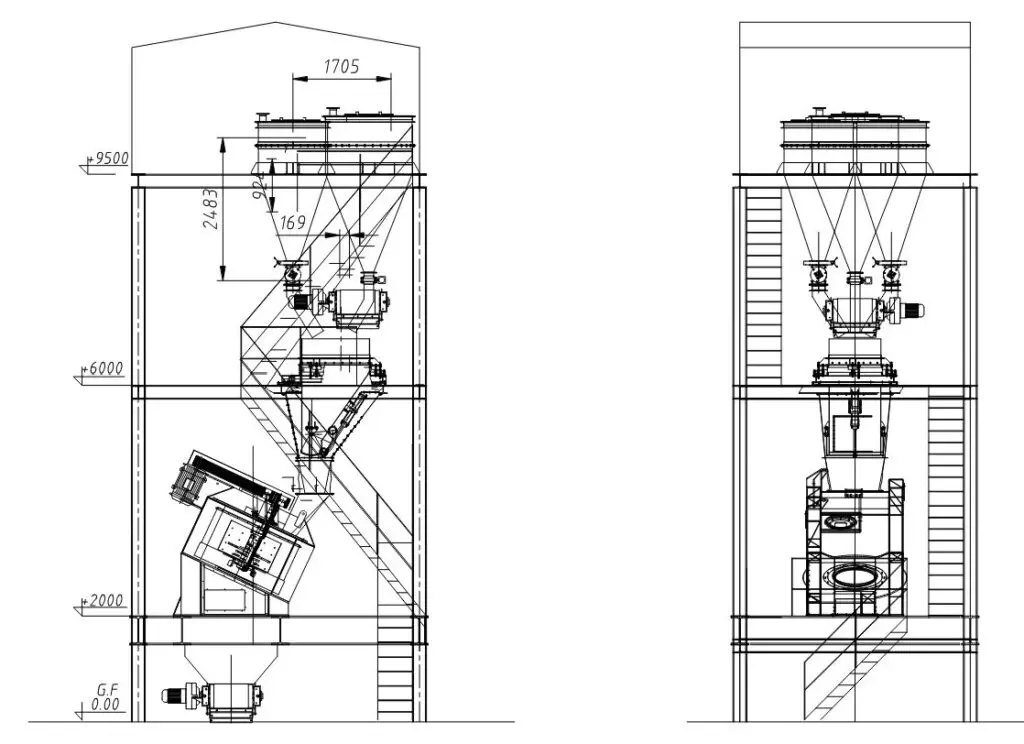

In response to the operational demands of a foundry requiring high-quality and uniform green sand mixtures, a comprehensive engineering and consulting project was carried out to design and build a one-ton green sand mixer. Inspired by globally recognized models, the mixer was engineered with a rotating drum body to enhance mixing homogeneity and eliminate dead zones during operation.

Key aspects of the project included:

-

Optimization of the mechanical structure and power transmission system for efficient blending

-

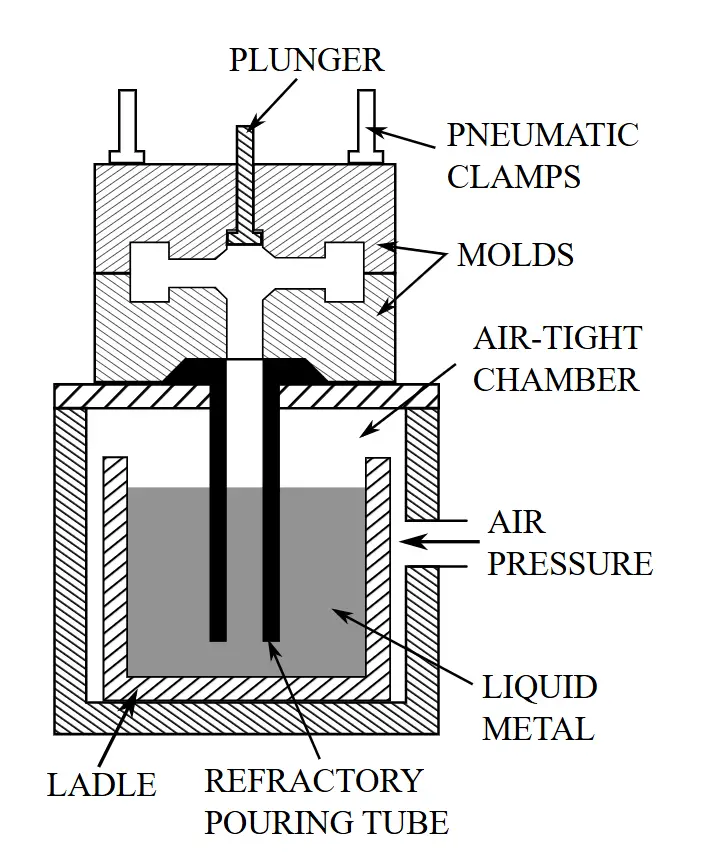

Integration of precise moisture control mechanisms to maintain ideal molding properties

-

Selection and design of wear-resistant components to ensure extended equipment life

-

Simulation-based evaluation to analyze material flow and predict performance

-

Tailored design of sand inlet/outlet systems in line with actual production requirements

Project Achievements:

-

✅ High homogeneity in sand and additive distribution

-

✅ Reduction of sand lumps under 3 mm to below 2%

-

✅ Improved wear life of internal components and minimized downtime

-

✅ Long-term stable performance under full operational load

-

✅ Enhanced molding sand quality and reduced surface defects in castings

This project showcases a successful integration of technical expertise and practical manufacturing needs, resulting in significant improvements in casting quality, process stability, and operational efficiency.