✅ Metallurgical Investigation of Oxide Layer Formation Due to Turbulence in Gray Iron Casting

🔹 Introduction

In gray cast iron production, turbulent metal flow during pouring can lead to the entrapment of oxide films within the casting, especially in complex gating systems or high-velocity pours. These thin oxide layers may remain undetected in standard inspection procedures, only appearing after machining as subsurface inclusions or defects on functional surfaces.

This industrial research project aimed to investigate the formation mechanism, morphology, and metallurgical impact of these oxides using advanced techniques. The study was driven by a series of post-machining defects observed in a critical component line, triggering the need for deeper scientific analysis to enhance process control.

🔹 Methodology

The project involved a multi-step approach:

-

Sample Selection from affected production batches

-

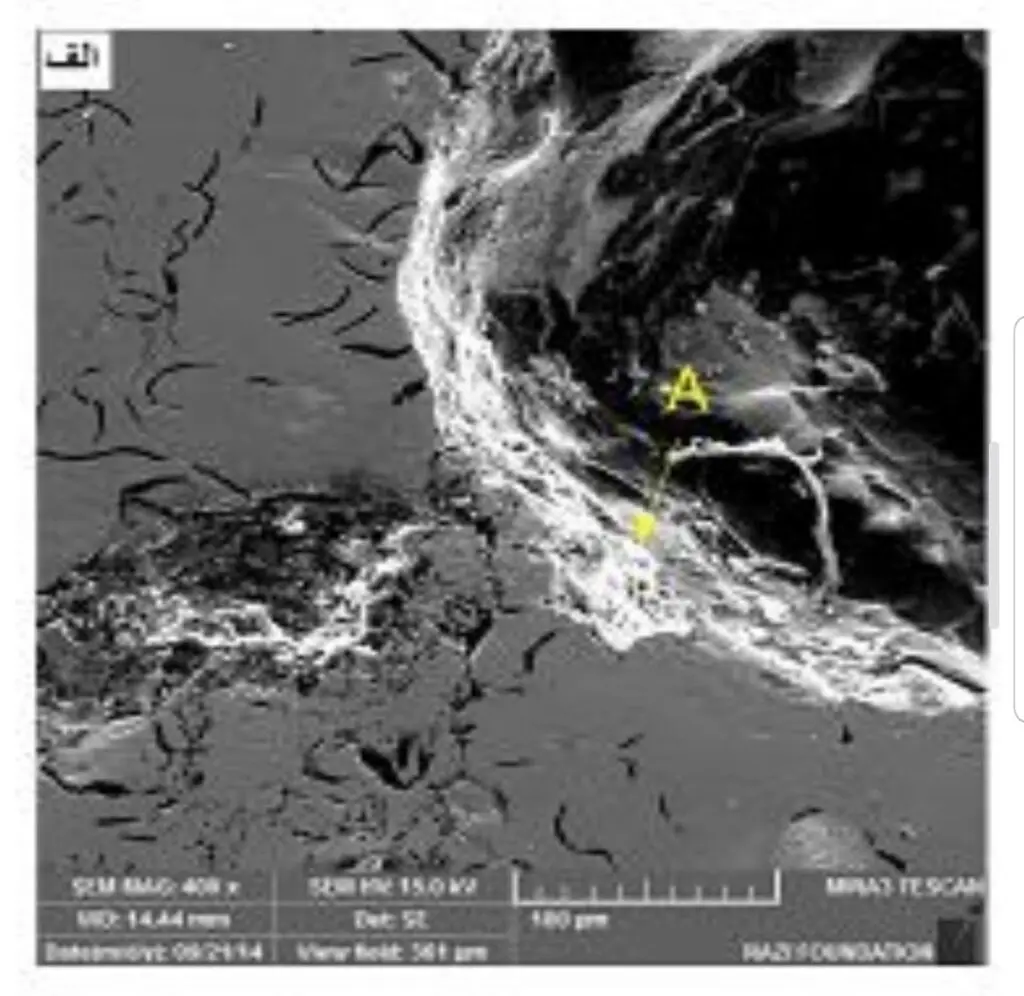

Advanced Metallography using deep etching and scanning electron microscopy (SEM)

-

Surface and Interface Analysis via EDS and X-ray mapping

-

Flow pattern analysis using casting simulation tools

-

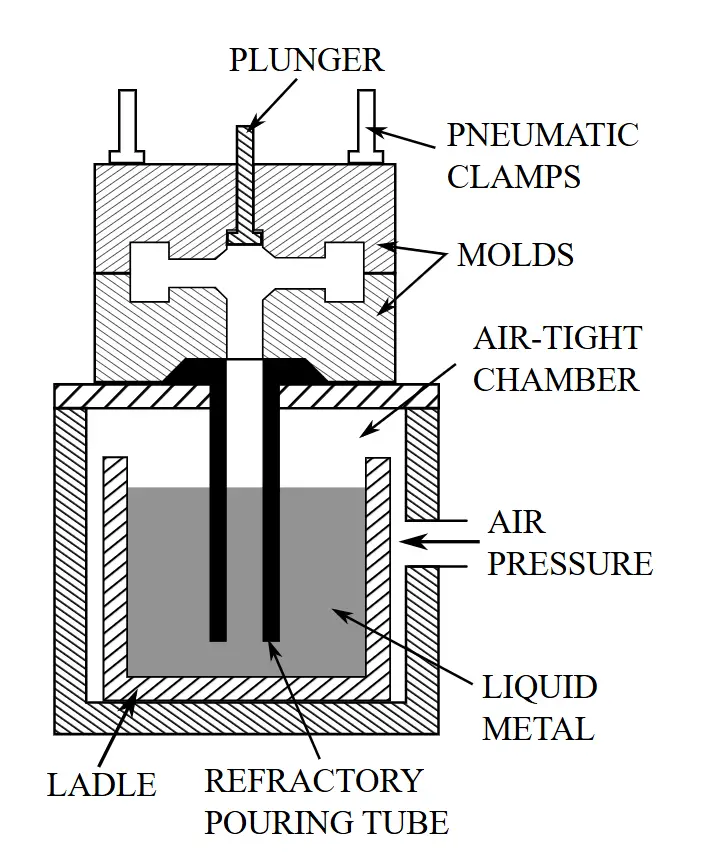

Review of gating design and pouring practices to identify sources of turbulence

The focus was on correlating melt behavior with defect formation, particularly under turbulent conditions common in automated pouring systems.

🔹 Key Achievements

-

✅ Identification of oxide bifilms associated with turbulent surface folding

-

✅ Characterization of oxide inclusions as aluminum-silicon-manganese-rich films

-

✅ Establishing the link between pouring velocity and sub-surface defects

-

✅ Recommendations for improved gating design to minimize turbulence

-

✅ Publication of the results in a leading peer-reviewed metallurgy journal in the U.S., later cited by academic and industrial researchers

🔹 Conclusion

This research bridged the gap between practical foundry challenges and academic analysis. The findings enabled improved gating system design, better melt handling practices, and more accurate defect prediction leading to higher-quality gray iron castings with fewer post-machining failures