🔧Gray and Ductile Iron Casting Process Optimization

At **ARAD Foundry Analysis**, we offer specialized solutions for optimizing **gray iron and ductile iron casting processes**. In this featured project, we helped a major foundry enhance productivity, reduce scrap, and improve casting quality through data-driven engineering and hands-on improvements.

🔍 Key Challenges Identified

Following a comprehensive technical audit of the casting workflow, our team discovered several root problems affecting the overall performance:

– ⚠️ Inconsistent casting quality in both gray and ductile iron

– 🚮 High levels of scrap and rework

– ⏱️ Inefficient melting and molding cycles

– 🧪 Delays in quality control and feedback

These issues were directly impacting product reliability, cost efficiency, and production throughput.

🛠️ Our Engineering-Based Solutions

To address these challenges, we implemented a combination of simulation, shop floor analysis, and real-time adjustments, including:

– ✅ Optimization of **melt chemistry** to enhance metallurgical structure and strength

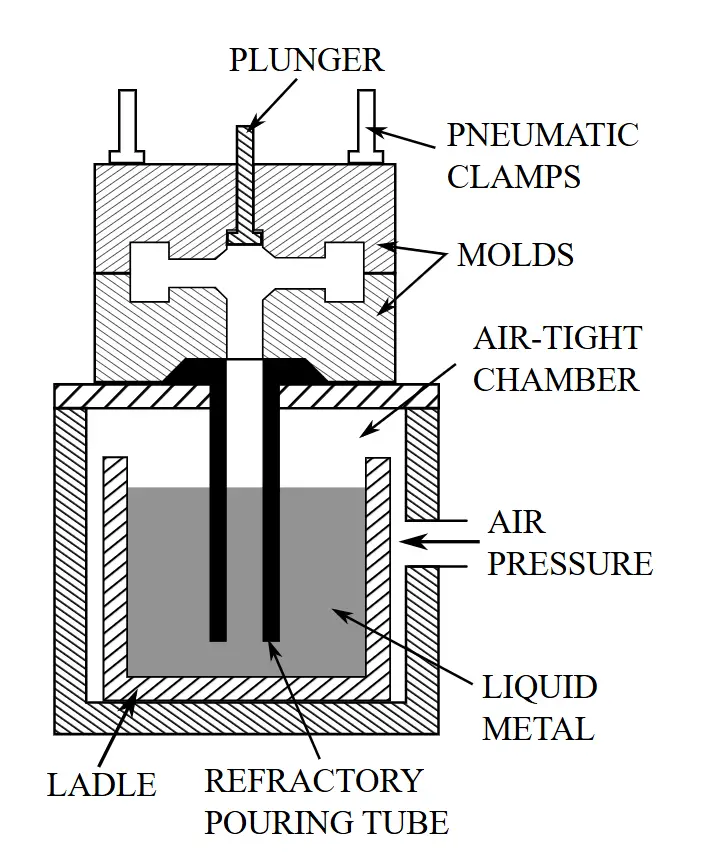

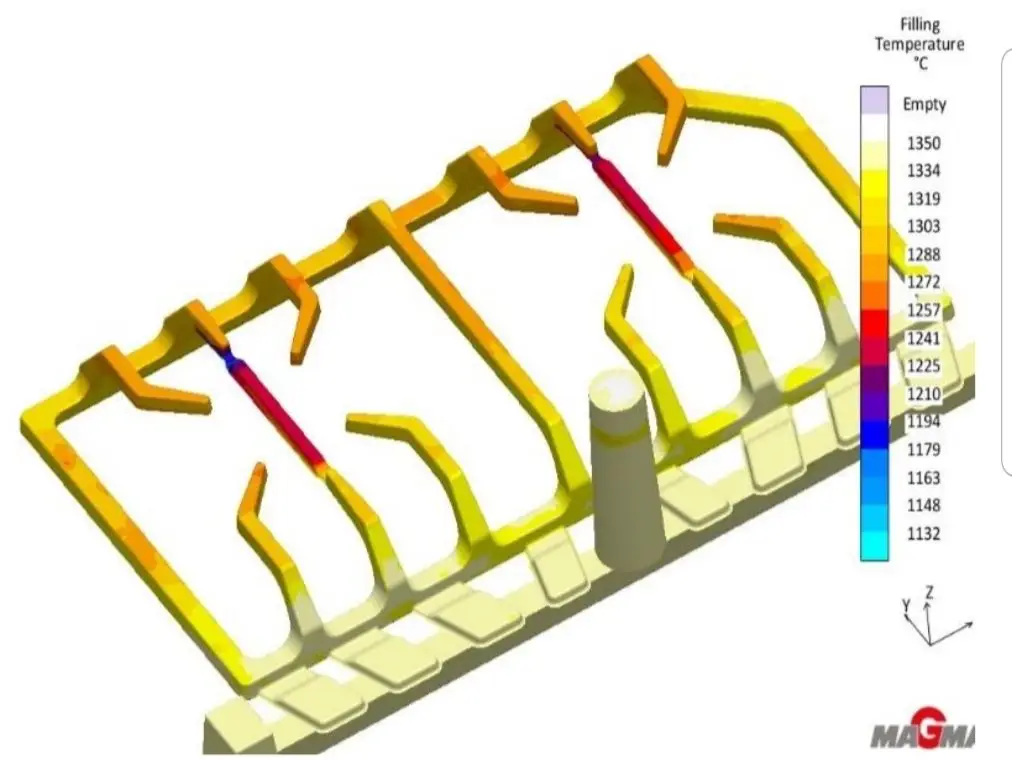

– ✅ Complete **redesign of gating and feeding systems** to reduce porosity and eliminate turbulence

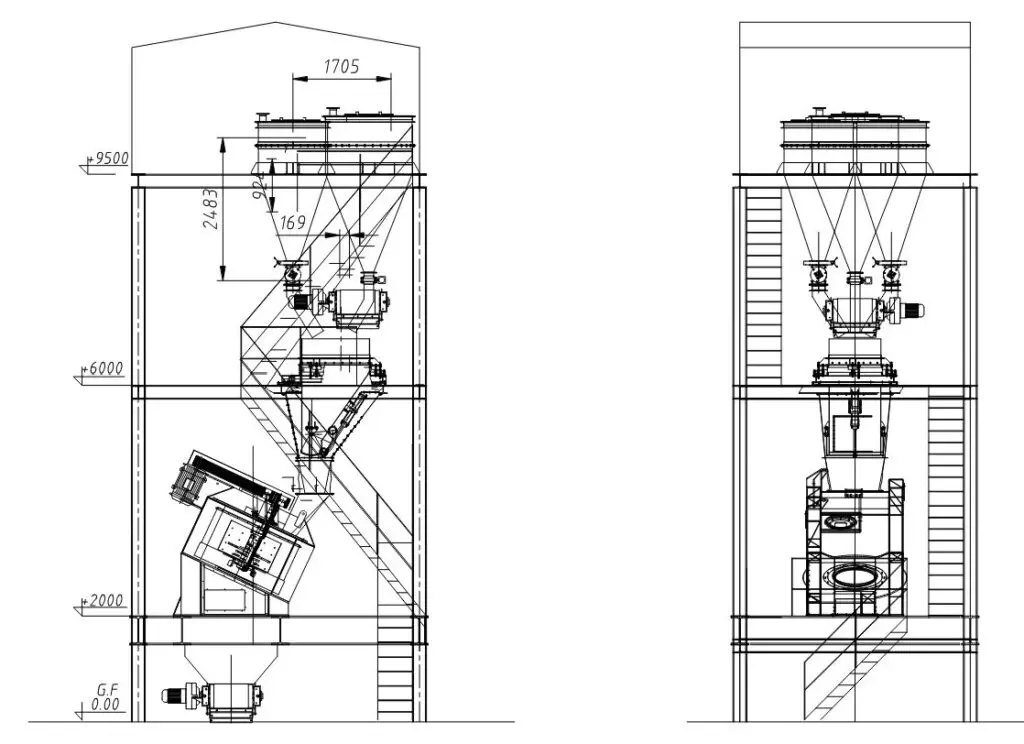

– ✅ Refinement of **melting and holding practices** to minimize thermal variation

– ✅ Implementation of structured **quality control checkpoints** to enable fast feedback and corrective actions

📈 Results and Achievements

Within weeks of implementation, the foundry experienced the following measurable improvements:

– 📉 20% reduction in overall **scrap and rejection rates**

– 💪 Improved **mechanical properties and microstructure consistency**

– 🔄 Shortened cycle times and reduced **downtime**

– 📦 Increased casting **yield and process reliability**

This project highlights the potential of targeted **casting process optimization** to drive tangible benefits across foundry operations.

—

🌐 Interested in improving your iron casting line?

[Contact our technical team](https://www.afacasting.com/contact) to start your optimization journey.